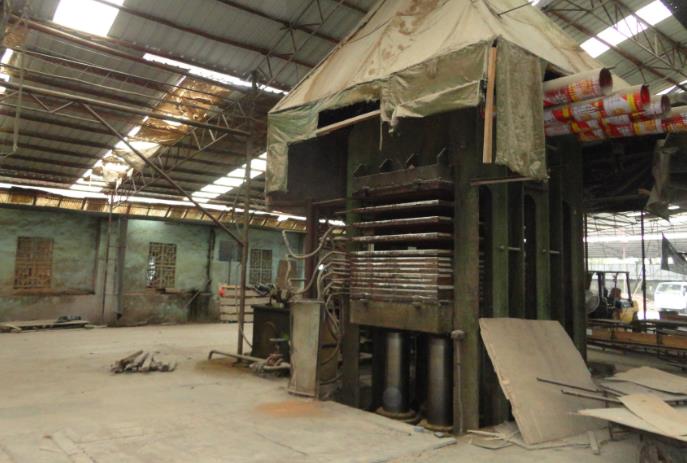

Structural composition of plywood hot press equipment

Plywood hot press machine is the core equipment in production, which uses heat and pressure to bond and solidify the slab. Its main structure is composed of the following precision systems:

1、 Main framework structure

This is the basic pressure bearing part of the equipment. A highly rigid closed force frame is usually composed of an upper crossbeam, a lower crossbeam, four (or more) columns, and nuts, ensuring stability and no deformation during the hot pressing process.

2、 Hydraulic system

As a source of pressure, the system consists of a high-pressure pump station, a control valve group, a large plunger cylinder, and pipelines. Oil cylinders are often installed on the lower or upper crossbeam, and are driven by hydraulic oil to lift and lower the plunger, thereby applying and maintaining the required enormous pressure on the slab.

3、 Heating system

According to different heat sources, it can be divided into forms such as steam heating, thermal oil heating, and electric heating. The core is the hot press plate, which is a thick steel plate with uniform flow channels cast inside. The heat medium circulates in it, efficiently transferring heat to the slab. Multiple hot pressed plates are alternately arranged through heating layers to achieve the compression of multiple sheets at once.

4、 Control system

The central nervous system of modern hot press machines. By using PLC and touch screen, the setting, adjustment and fully automatic control of the three core process parameters of pressure, temperature and time are integrated to ensure the accuracy and stability of product quality.

5、 Auxiliary device

Including loading and unloading machines, pad return systems, etc., they are linked with the host to form an automated production line, greatly improving production efficiency and safety.

These systems work together to ensure efficient and high-quality compression molding of plywood.