How to control the energy consumption of new lime vertical kilns

With the tense global energy situation and increasingly strict environmental requirements, how to effectively control the energy consumption of new lime vertical kilns has become an important issue facing the lime production industry. The new type of lime vertical kiln has achieved a significant reduction in energy consumption and an improvement in energy utilization efficiency by adopting advanced technology and equipment.

1、 Raw material selection and pretreatment

The quality and properties of raw materials have a direct impact on the energy consumption of lime vertical kilns. Firstly, limestone raw materials with stable quality and reasonable chemical composition should be selected, avoiding the use of materials with high impurities and high firing temperatures. Secondly, pre-treatment of the raw materials, such as crushing, sieving, etc., ensures uniform particle size, which is beneficial for heat transfer and uniform calcination during the calcination process. In addition, controlling the moisture content of raw materials is also an important measure for energy conservation. Excessive moisture content can increase heat consumption and exhaust emissions.

2、 Optimization of kiln structure and materials

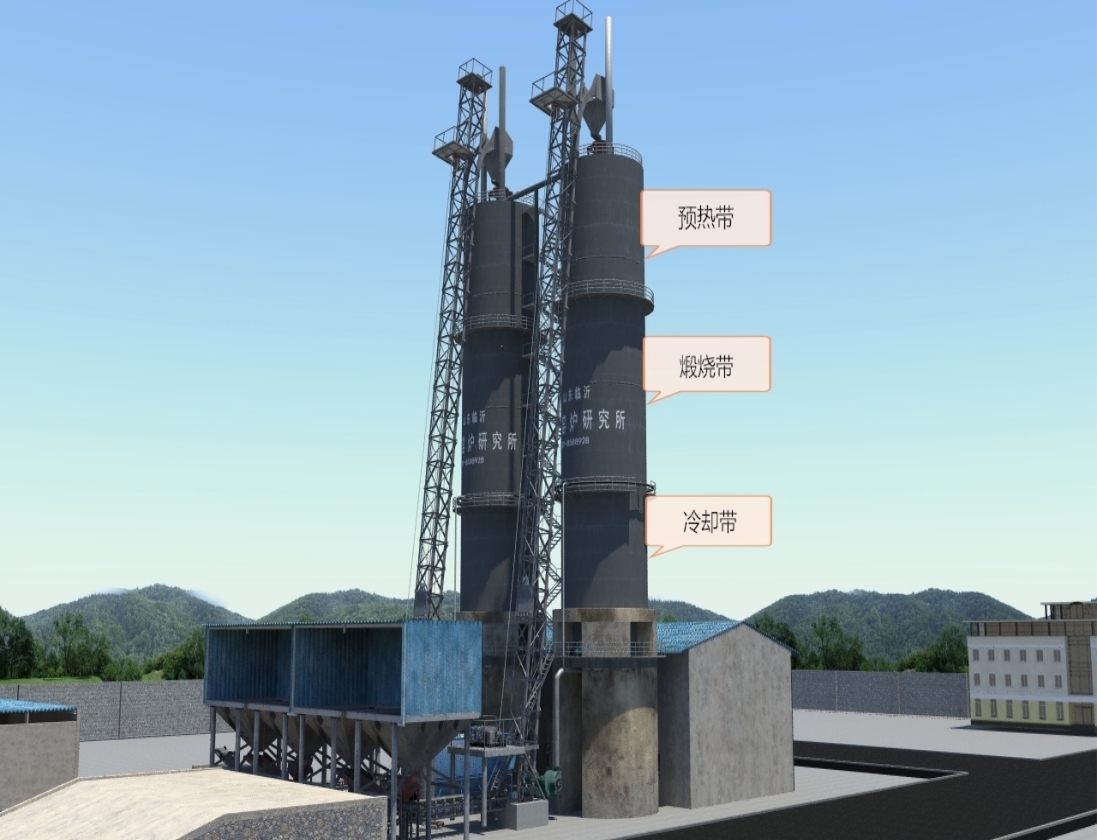

The structure and materials of kilns have a significant impact on energy consumption. The new lime vertical kiln optimizes the insulation performance of the kiln and uses efficient insulation materials to reduce heat loss. At the same time, improving the structural design of kilns, such as optimizing the structure of combustion chambers, heat exchangers, and other components, can enhance thermal efficiency. In addition, the use of new refractory materials improves the service life and stability of the kiln, reduces the frequency of maintenance and replacement, and thus lowers energy consumption.

3、 Efficient combustion and thermal control

The combustion system is a key link in energy-saving for lime vertical kilns. The new lime vertical kiln uses efficient and low pollution burners to ensure full combustion of fuel and reduce unburned losses. At the same time, optimize the ratio of combustion air to fuel, control the excess air coefficient, and improve combustion efficiency. Strengthen thermal control, achieve precise control of calcination temperature and time, avoid over burning or under burning phenomena, and reduce energy consumption.

4、 Waste gas and heat recovery

The lime vertical kiln produces a large amount of high-temperature exhaust gas during the calcination process, which contains abundant waste heat resources. The new type of lime vertical kiln uses waste gas heat recovery technology, such as heat pipe heat exchangers, hot blast stoves, etc., to recover and utilize the heat in the waste gas, which can be used to preheat the air entering the kiln, dry raw materials, etc., thereby reducing energy consumption.

5、 Automation and Intelligent Control

Introducing automation and intelligent technology to achieve precise control and optimized operation of lime vertical kilns is an important means to improve energy efficiency. The new lime vertical kiln adopts advanced sensors, control systems, and data analysis technology to achieve real-time monitoring and precise control of the calcination process, optimize combustion and calcination parameters, and reduce energy consumption. Meanwhile, intelligent technology can also achieve fault warning and remote maintenance, improving the stability and reliability of equipment operation.

6、 Construction of Energy Management System

Establish a comprehensive energy management system, set scientific energy-saving goals and measures, strengthen monitoring and analysis of energy consumption, and timely discover and solve energy-saving problems. By implementing regular maintenance and overhaul, ensure that the equipment is in good operating condition, maintain its thermal efficiency, and reduce energy consumption. At the same time, establish energy-saving incentive mechanisms and standard systems to stimulate the enthusiasm of enterprises to carry out energy-saving work and promote the overall improvement of the industry's energy-saving level.

The energy consumption control strategy of the new lime vertical kiln covers multiple aspects such as raw material selection and pretreatment, kiln structure and material optimization, efficient combustion and thermal control, waste gas and heat recovery, automation and intelligent control, and energy management system construction. The implementation of these strategies not only helps to reduce the energy consumption level and production costs of lime vertical kilns, improve the profitability and market competitiveness of enterprises, but also brings significant environmental benefits and promotes sustainable development.