EPC general contracting of new lime kiln manufacturer

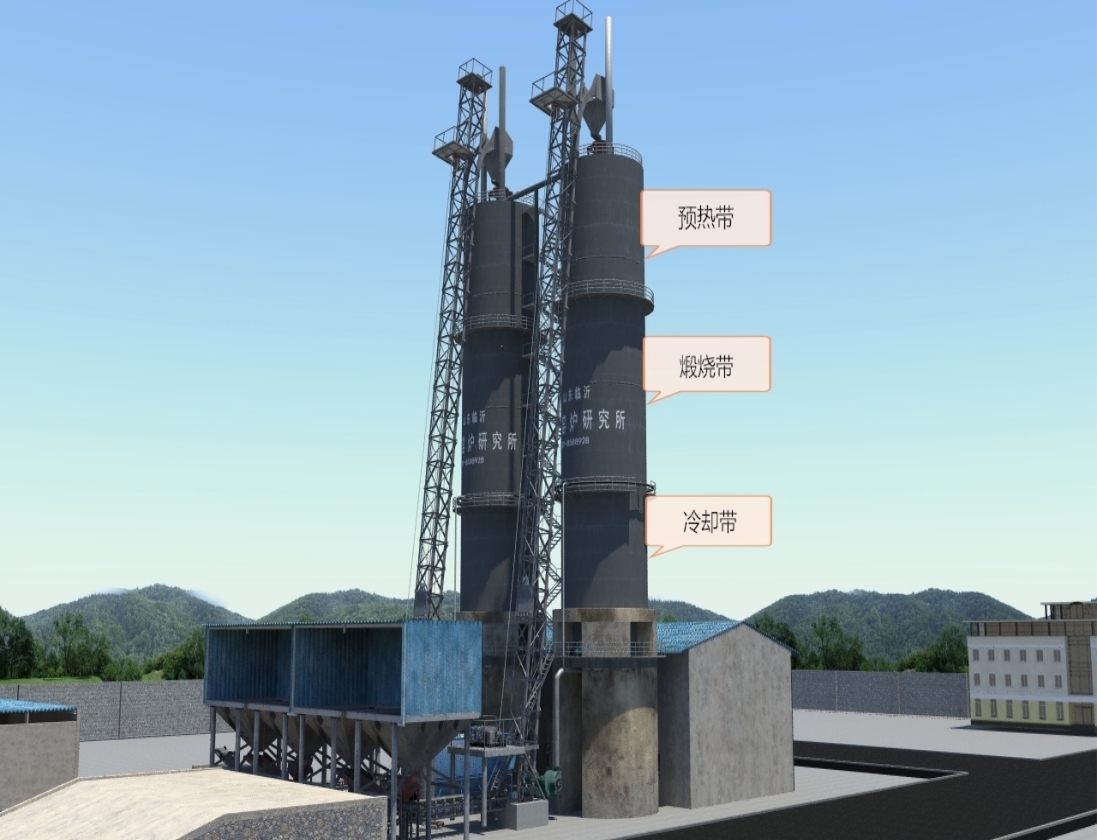

In the field of lime production, new lime kilns are gradually becoming the mainstream of the market due to their advantages of high efficiency, environmental protection, and energy conservation. The EPC general contracting services provided by numerous new lime kiln manufacturers have brought comprehensive solutions to lime production enterprises, promoting the entire industry to a higher level of development.

The EPC general contracting model of the new lime kiln manufacturer covers all aspects of the project, including design, procurement, and construction. Taking Shanghai Baoye as an example, it has demonstrated strong EPC general contracting capabilities in multiple lime kiln projects. In the EPC general contracting project of Indonesia's OBI 600000 tons/year lime production line, facing the challenge of extreme high temperature climate, the project team adhered to the corporate spirit of "surpassing oneself and daring to be the first", deepened comprehensive control in production, safety, quality and other aspects, and successfully completed the pouring of the main foundation structure of the second kiln body, laying a solid foundation for subsequent construction. The project is located on Obi Island in North Maluku Province, Indonesia, with a total construction period of 380 calendar days. After completion, it will help promote the development of the local lime industry.

The advantages of the EPC general contracting model are significant. For property owners, adopting a fixed price contract is beneficial for cost control, with clear responsibilities and simple management, allowing them to focus more energy on the key influencing factors of the project. For general contractors, being fully responsible for project implementation can fully integrate resources, improve overall project revenue, reduce project risks, and enhance market competitiveness.

However, the EPC general contracting model also faces some challenges. If the selection of general contractors is limited, there is a high requirement for the comprehensive ability of the enterprise; Risk management is centralized, and the performance risk of the general contractor is high; The total contract price is difficult to determine, and the difficulty of controlling cost risks is high; The difficulty of project coordination has increased, involving multi-party cooperation.

To cope with these challenges, new lime kiln manufacturers are constantly improving their own strength. Shanghai Baoye has made a breakthrough in the field of new lime kilns, entering the chemical and calcium carbide industries, and occupying 70% of the market share with general contracting projects. The exploration and creation of a new method for the recovery and utilization of exhaust gas and waste heat from sleeve lime kilns not only bring huge economic benefits to enterprises, but also significantly reduce air pollution and receive high government subsidies. At the same time, Baoye focuses on technological innovation, and its independently developed plastic ceramic welding repair technology fills the domestic gap and solves the problem of brick falling off the arch bridge of the sleeve type lime vertical kiln.

In the management of EPC general contracting projects, new lime kiln manufacturers have also accumulated rich experience. Taking the EPC project of Shenmu Calcium Carbide Group's 3 * 600t/d active lime kiln as an example, Shanghai Baoye has been fully committed to promoting project construction since the start of construction, normalizing epidemic prevention and control, adhering to the bottom line of safety and environmental protection, and relying on rich experience and excellent quality to ensure that the project progresses as planned.

With the continuous development of the lime industry, the EPC general contracting services of new lime kiln manufacturers will play an increasingly important role. Through continuous innovation and optimization, these manufacturers will lead the lime production industry towards a new era of greater efficiency, environmental protection, and intelligence.