What is the proportion of three zones in a lime vertical kiln

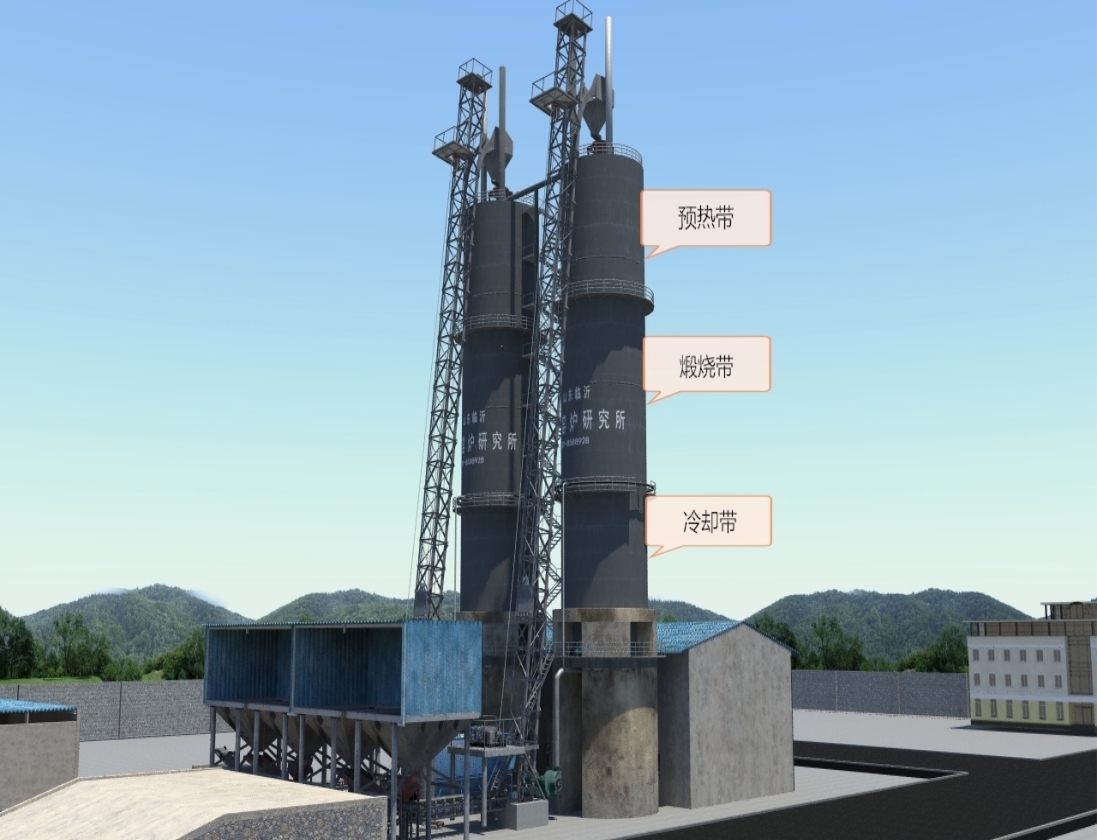

As an important equipment for lime production, the pre heating zone, calcination zone, and cooling zone (hereinafter referred to as the "three zones") inside the lime vertical kiln play a crucial role, and their proportional relationship has a profound impact on the quality, efficiency, and energy consumption of lime production. Generally, the ratio of these three zones is 2:1:3.

What is the proportion of three zones in a lime vertical kiln

1、 Pre tropical

(1) Function and Characteristics

The preheating zone is located at the upper part of the lime vertical kiln, mainly responsible for preheating the limestone raw materials entering the kiln. Limestone gradually heats up in this area, removing moisture and some volatile components. The evaporation of water helps to reduce energy consumption during the subsequent calcination process, while the discharge of volatile matter also creates conditions for the smooth decomposition of limestone. The temperature in the preheating zone is relatively low, generally gradually rising from room temperature to several hundred degrees Celsius. The specific temperature range may vary depending on factors such as kiln type, raw material characteristics, and production process.

(2) Proportion analysis and importance

In the ratio of 2:1:3, the proportion of pre tropical zone is 2. This larger proportion of setting is reasonable. Firstly, a sufficiently long preheating zone can fully preheat limestone, achieving a smooth temperature rise and avoiding limestone cracking or internal structural damage caused by rapid temperature changes. In this way, when entering the calcination zone, limestone can better adapt to high temperature environments, which is conducive to the uniform decomposition reaction of calcium carbonate. Secondly, by extending the preheating process, the thermal utilization efficiency of the entire kiln system can also be improved. The preheated limestone absorbs a portion of the heat, allowing the heat generated by subsequent fuel combustion to be more effectively transferred to the calcination zone, reducing heat loss, thereby reducing energy consumption and improving production efficiency.

2、 Calcination belt

(1) Core position and function

The calcination zone is the core area of the lime vertical kiln and a key link in determining the quality of lime. In this region, calcium carbonate (CaCO) in limestone undergoes decomposition reactions at high temperatures, producing calcium oxide (CaO) and carbon dioxide (CO ₂). The temperature of the calcination zone is usually high, generally between 800-1200 ℃, and the specific temperature needs to be precisely controlled according to the quality and production requirements of the limestone. In order to ensure that calcium carbonate can be fully decomposed, the calcination zone needs to provide sufficient heat and suitable reaction time.

(2) Interpretation of Proportional Meaning

The proportion of calcination zone in the three zone ratio is 1. Although its proportion is relatively small, its role is crucial. The moderate ratio of calcination zones is to ensure that limestone can be fully calcined at high temperatures without excessive calcination. If the calcination zone is too long, it may lead to excessive fuel consumption, increase production costs, and may also cause over burning of lime, affecting its activity and quality; If the calcination zone is too short, it will cause incomplete decomposition of limestone, resulting in residual undecomposed calcium carbonate in the lime product and reducing the effective component content of lime. Therefore, controlling the proportion of calcination zone within a reasonable range is of great significance for ensuring the quality and yield of lime and optimizing energy utilization.

What is the proportion of three zones in a lime vertical kiln

3、 Cooling belt

(1) Function and Operating Principle

The cooling zone is located at the lower part of the lime vertical kiln, and its main function is to cool the calcined lime product. During the cooling process, the temperature of the lime product gradually decreases, while transferring the heat it carries to the air entering the kiln, thereby achieving preheating of the air. The preheated air can be used as combustion air to enter the calcination zone, improving the combustion efficiency of the fuel and further saving energy. The temperature of the cooling zone gradually decreases from the high temperature of the calcination zone to near room temperature. There are generally two cooling methods: natural cooling and forced cooling, depending on the design and production requirements of the kiln.

(2) Basis and advantages of proportion setting

In the three belt ratio, the cooling belt accounts for 3, which is based on multiple factors. On the one hand, a longer cooling belt can ensure that the lime product is fully cooled, allowing it to have a suitable temperature when discharged from the kiln, facilitating subsequent storage, transportation, and use. If the cooling is not sufficient, high-temperature lime products may undergo chemical reactions with the outside air, affecting their quality, and there may also be safety hazards during storage and transportation. On the other hand, the preheating effect of the cooling belt on the air can improve the comprehensive utilization efficiency of energy. A large amount of heat exchange occurs in the cooling zone, which increases the temperature of the air entering the calcination zone, reduces the heat required for fuel combustion, thereby reducing fuel consumption and lowering production costs. Meanwhile, a reasonable cooling zone ratio can also adjust the airflow distribution inside the kiln, ensuring the stability and reliability of kiln operation.

4、 The comprehensive impact and adjustment strategy of the three belt ratio

(1) The overall impact on the production process

The ratio of pre heating zone, calcination zone, and cooling zone is 2:1:3, which is a relatively reasonable ratio obtained through long-term practice and optimization. It enables the reasonable distribution and utilization of heat in the production process of lime vertical kilns, ensuring smooth preheating, sufficient calcination, and effective cooling of limestone, thereby producing qualified lime products. At the same time, this proportional relationship also helps to maintain the stability of the airflow inside the kiln, reduce heat loss and pollutant emissions, improve production efficiency and energy utilization, and reduce production and equipment maintenance costs.

(2) Adjustment factors and methods in actual production

However, in actual production, due to changes in raw material composition, particle size, fuel type and quality, production scale, and kiln equipment performance, it may be necessary to adjust the three belt ratio appropriately. For example, if the particle size of the raw material is large and the heat transfer rate is relatively slow, it may be necessary to extend the length of the preheating zone appropriately to ensure that the limestone can be fully preheated; If the calorific value of the fuel is low, in order to ensure the temperature of the calcination zone, it may be necessary to adjust the fuel supply and the ratio of the calcination zone appropriately. The methods for adjusting the proportion of the three belts mainly include adjusting the material distribution method, ventilation rate, fuel addition amount, and position inside the kiln. Through these adjustment measures, the kiln can adapt to different production conditions, ensuring stable lime production and consistent product quality.

What is the proportion of three zones in a lime vertical kiln

The ratio of 2:1:3 for the three zones in a lime vertical kiln is a ratio of significant importance in both theory and practice. It fully considers the needs and interrelationships of various links in the lime production process, and achieves efficient, high-quality, and energy-saving lime production through reasonable heat distribution and airflow control. In actual production, we should flexibly adjust the ratio of the three belts according to specific situations to ensure the optimal operating state of the kiln and provide strong support for the development of the lime industry. At the same time, with the continuous advancement of technology and the continuous improvement of production processes, research and optimization of the three belt ratio of lime vertical kilns will continue to be carried out to further improve the efficiency and quality of lime production.