What is the specific maintenance process for plywood hot press equipment

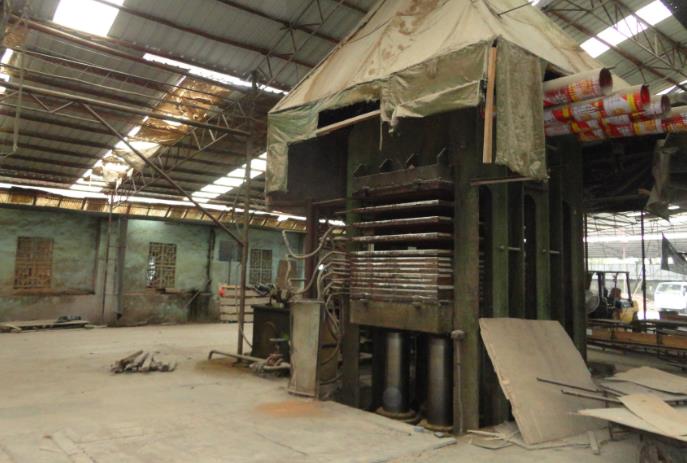

Plywood hot press machine is a crucial equipment in the production process of plywood. Its main function is to tightly bond wood and adhesive together through high temperature and high pressure. Regular maintenance is essential to ensure the normal operation of the hot press and extend the service life of the equipment. The following is the specific process for maintaining the plywood hot press equipment.

1、 Daily inspection

Appearance inspection

Before use every day, the operator should inspect the appearance of the hot press machine to ensure that there are no obvious damages, leaks, or loose parts. Pay attention to checking the hydraulic oil pipes, electrical circuits, and control panel to ensure that there are no abnormal phenomena.

Lubrication system inspection

Check the oil level and quality of the lubricating oil, and replace it if necessary. Ensure that all lubrication points have been lubricated, especially moving parts and bearings, to reduce friction and wear.

Fastener inspection

Check the tightening of all bolts and nuts to ensure they do not loosen during operation. Torque wrenches can be used regularly for calibration to ensure that the tightening torque meets the standard.

2、 Regular maintenance

Weekly maintenance

Conduct a detailed inspection of the main components of the hot press every week, including:

Hydraulic system: Check the quality and level of hydraulic oil, and replace the oil if necessary. At the same time, check whether there is any leakage in the hydraulic cylinder to ensure good sealing of the cylinder.

Electrical system: Check the connection of the motor and its cables to ensure there is no wear or damage. Test all switches and indicator lights on the control panel to ensure they are functioning properly.

Monthly maintenance

Perform more comprehensive maintenance every month, including:

Cleaning equipment: Clean the dirt and debris around the hot press machine to maintain a clean working environment. Special attention should be paid to cleaning the exhaust and intake ports of the hot press to ensure good ventilation.

Hot press plate inspection: Check the flatness and temperature uniformity of the hot press plate. If necessary, perform grinding treatment to ensure that the hot pressing plate does not affect the bonding quality during operation.

Quarterly maintenance

Conduct in-depth maintenance every quarter, including:

Hydraulic oil replacement: Regularly replace the hydraulic oil and filter element according to the usage of the hydraulic oil. Ensure the internal cleanliness of the hydraulic system and avoid the impact of pollutants on the system.

Motor maintenance: Clean and insulation test the motor to ensure normal operation and good electrical insulation. Regularly check if the fan is running properly to prevent overheating.

3、 Annual maintenance

Comprehensive maintenance

Annual comprehensive maintenance of the hot press machine, including disassembly and inspection of all key components such as hydraulic pumps, valves, hot press plates, and control systems. Replace worn parts as necessary to ensure that the equipment is in optimal working condition.

System upgrade

Check the control system and software of the hot press, and upgrade if necessary to improve the automation level and safety performance of the equipment. Update the equipment operation manual and maintenance records to ensure that operators can refer to them at any time.

security check

Check the safety protection devices of the hot press, such as emergency stop button, overload protection, and protective cover. Ensure that all safety devices are functioning properly and ensure the safety of operators.

4、 Operator training

Regularly train operators to understand the working principle, maintenance process, and safety operating procedures of the hot press machine. Ensure that operators can correctly identify abnormal situations in equipment and handle them in a timely manner to reduce equipment failure rates.

5、 Record and feedback

After each maintenance, the operator should record in detail the maintenance content and results, including the replaced parts, the date of hydraulic oil replacement, and any problems and solutions found. Regularly analyze these records and summarize the best maintenance plan to optimize equipment management.

The maintenance of plywood hot press is a systematic and complex task, and a scientific maintenance plan must be developed based on the actual operation of the equipment. By conducting daily inspections, regular maintenance, and annual inspections, the service life of the hot press machine can be effectively extended, ensuring the quality and efficiency of plywood production. Regular training and feedback mechanisms can improve the skill level of operators and the management level of equipment, ensuring the smooth operation of plywood production lines.