What is the structure of a plywood sanding machine

The plywood sanding machine is a key equipment used for surface processing in the production process of plywood, and its structural design directly affects the sanding effect and production efficiency. The main structural components and functions of the plywood sanding machine are as follows:

1、 Main structural components

The plywood sanding machine mainly consists of the following parts:

Rack: The rack is the supporting structure of the sanding machine, usually welded from high-quality steel, with sufficient strength and rigidity to ensure smooth operation of the machine.

Conveyor system: The conveyor system is used to feed plywood into and out of the sanding area, usually consisting of conveyor belts, rollers, and drive devices. The speed of the conveyor belt can be adjusted to accommodate plywood of different thicknesses and materials.

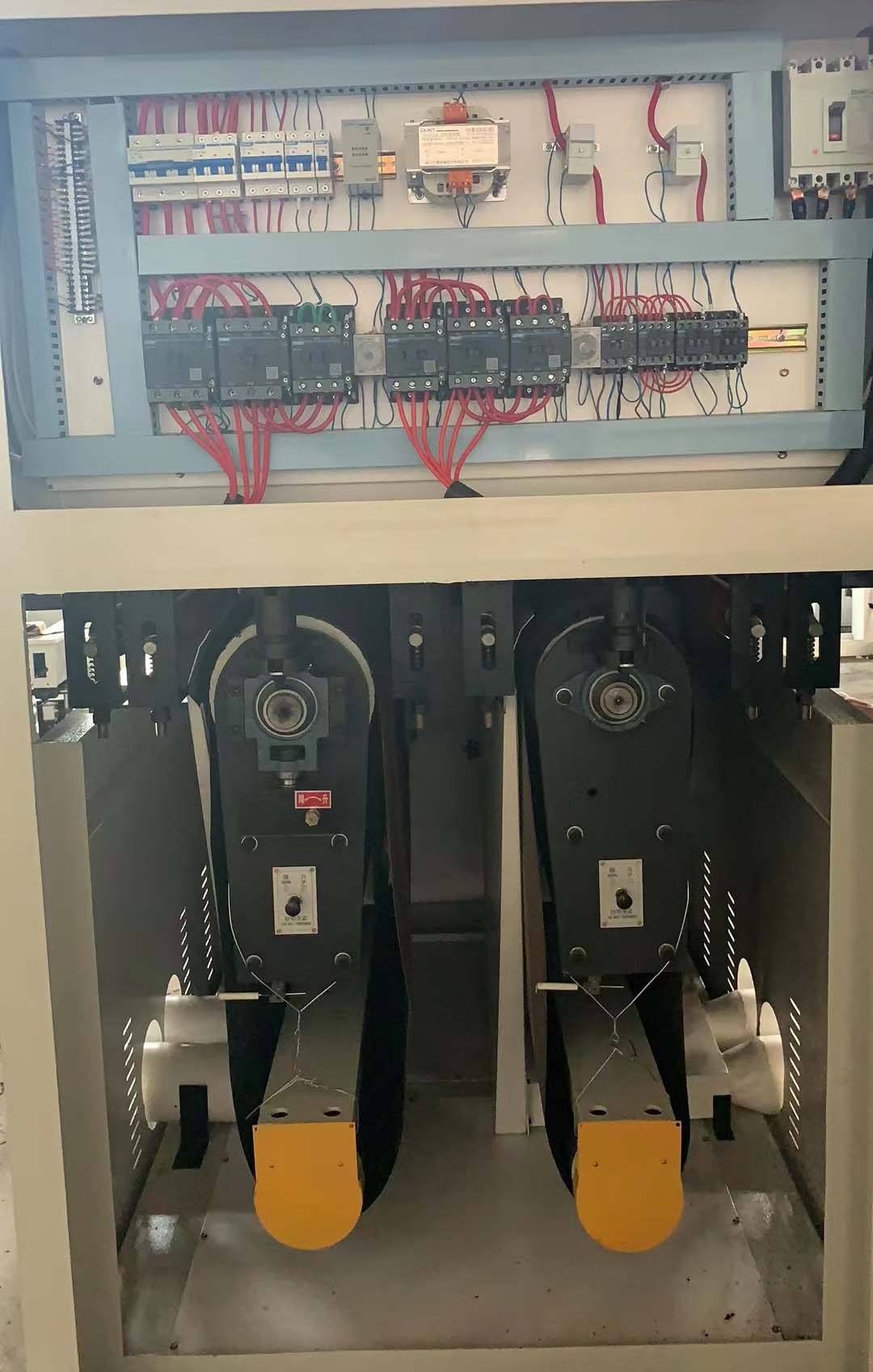

Sanding system: The sanding system is the core part of the sanding machine, consisting of a sanding head, sand belt, and clamping device. A sanding head is usually equipped with multiple sanding rollers, and the sanding belt is wrapped around the sanding rollers, which are driven by a motor to rotate at high speed to polish the surface of the plywood. The clamping device is used to press the sand belt onto the surface of the plywood to ensure the sanding effect.

Dust removal system: The dust removal system is used to collect the dust generated during the sanding process and maintain a clean working environment. It usually consists of a vacuum hood, a pipe, and a dust collector.

Electrical control system: The electrical control system is used to control the operation of the sanding machine, including functions such as motor start, stop, speed adjustment, and belt tension.

2、 Structural characteristics of different types of sanding machines

According to different sanding methods, plywood sanding machines can be divided into the following types:

Broadband sanding machine: using a wide sanding belt, it can sand the entire width of plywood at the same time, with high efficiency and suitable for large-scale production.

Narrow band sanding machine: using narrow amplitude sand belts, it can finely sand the edges and irregular parts of plywood, suitable for small batch and multi variety production.

Double sided sanding machine: It can sand both the upper and lower surfaces of plywood at the same time, with high efficiency, suitable for occasions with high requirements for double-sided sanding.

The structural design of plywood sanding machine directly affects its performance and usage effect. With the continuous advancement of technology, plywood sanding machines are developing towards high efficiency, high precision, and automation to meet the growing production needs of the plywood industry.