What are the details to pay attention to when installing the rotary cutting blade on the veneer rotary cutting machine

During the use of the veneer rotary cutting machine, the installation of the rotary cutting blade is crucial, directly affecting the quality of rotary cutting and the stability of equipment operation. The following are the details to pay attention to when installing the veneer rotary cutting machine rotary cutting blade.

1、 Ensure stability

When installing a rotary cutter, stability is the primary consideration. Unstable rotary cutters may experience shaking, jumping, and other situations during operation, which not only affects the quality of rotary cutting but may also cause damage to the equipment. Using an altimeter or an altimeter equivalent to the centerline height of the card axis as a standard is crucial. By adjusting the supporting screws, make the height of the two end knives equal to the h value specified in the rotary cutting process. During the adjustment process, careful measurement is necessary to ensure the accuracy of the height. Once the height is determined, tighten all nuts to ensure that the rotary cutter is securely installed on the equipment.

2、 Rear angle adjustment

Without a rear angle tester, adjusting the rear angle requires experience. After changing the knife, carefully adjust the rear angle based on past operating experience. The size of the back corner directly affects the contact angle and cutting effect between the rotary cutter and the wood.

If the back angle is too large, the contact area between the rotary cutter and the wood decreases, the cutting force increases, which may cause the wood surface to be uneven and even crack; If the back angle is too small, the cutting efficiency of the rotary cutter may decrease, and problems such as tool jamming may occur. Therefore, when adjusting the back angle, factors such as the type of wood, hardness, and rotary cutting thickness should be comprehensively considered to achieve the best cutting effect.

3、 Observation during driving rotary cutting

When driving the rotary cutting machine, pay close attention to whether the entire cutting process is smooth. Smooth cutting is an important prerequisite for ensuring the quality of rotary cutting. If the cutting is not smooth, it may lead to uneven thickness of the veneer, and even defects such as wavy shapes.

During the rotary cutting process, attention should also be paid to observing the bright width of the friction between the blade of the rotary cutting blade and the surface of the wood segment. This bright width can serve as an important basis for determining whether the rear corner adjustment is appropriate. If the bright width is too large, it indicates that the back angle is too small and the cutting force is too high, and the back angle needs to be appropriately increased; If the bright width is too small, it indicates that the back angle is too large and the cutting efficiency is reduced. It is necessary to appropriately reduce the back angle.

4、 Preparation work before installation

Before installing the rotary cutter, it is necessary to inspect the tool. Ensure that the blade of the rotary cutter is sharp and free from defects such as notches and cracks. If the blade is damaged, it should be replaced or ground for repair in a timely manner. At the same time, the installation area of the equipment should be cleaned to remove debris, dust, etc., to ensure that the installation surface is flat and clean. This can ensure a tight fit between the rotary cutter and the installation site of the equipment, improving the stability of installation.

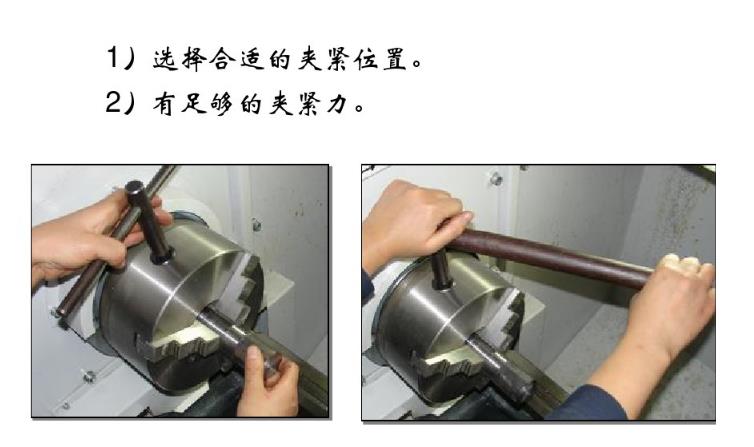

5、 Precautions during installation

During the installation of the rotary cutter, attention should be paid to operating procedures to avoid damaging the tool or equipment due to improper operation. Use appropriate tools for installation and avoid using brute force.

During installation, ensure that the installation direction of the rotary cutter is correct. Generally speaking, the blade of a rotary cutter should face the direction of wood feed to ensure cutting efficiency and smooth cutting.

6、 Inspection and debugging after installation

After installation, the rotary cutter should be inspected and debugged. Check if all fasteners are securely fastened and if the position of the rotary cutter is accurate.

Conduct a no-load test run and observe the operation of the rotary cutter to see if there are any abnormal noises, vibrations, or other phenomena. If any problems are found, the vehicle should be stopped for inspection in a timely manner, and the fault should be eliminated before proceeding with the formal rotary cutting operation.

Installing a veneer rotary cutting machine requires attention to multiple details, from ensuring stability to adjusting the rear angle, from preparation before installation to inspection and debugging after installation, every step is crucial. Only by taking these details seriously can we ensure the installation quality of the rotary cutting blade, improve the rotary cutting quality and operational stability of the veneer rotary cutting machine, and provide reliable guarantees for the production of wood processing enterprises.