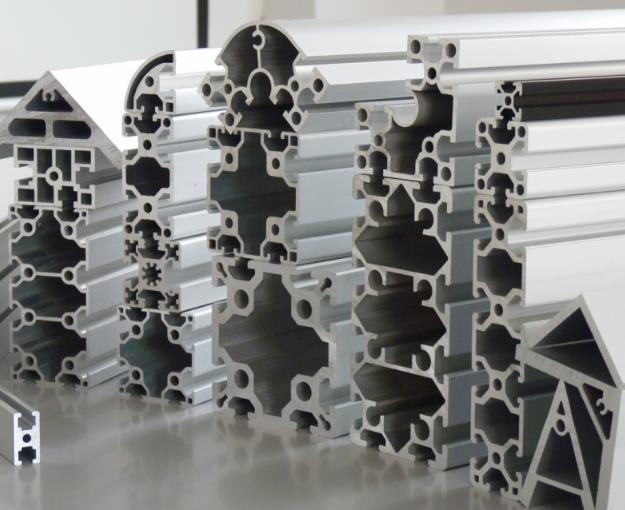

Surface treatment methods for industrial aluminum profiles

In modern industrial manufacturing, industrial aluminum profiles are widely used in various fields such as aerospace, automotive manufacturing, building decoration, and electronic equipment due to their excellent physical properties and processability. However, in order to improve the corrosion resistance, decorative and functional properties of aluminum profiles, surface treatment technology is particularly important. This article will introduce in detail several common surface treatment methods for industrial aluminum profiles, including chemical treatment and mechanical treatment.

1、 Chemical treatment method

1. Anodizing

Anodizing is one of the most common and widely used surface treatment methods for industrial aluminum profiles. This process is based on the principle of electrolysis, forming a dense layer of aluminum oxide film on the surface of the aluminum profile. This film not only effectively prevents aluminum from being corroded, but also has good wear resistance and insulation properties, making it particularly suitable for products used in harsh environments. The surface of anodized aluminum can be dyed in various colors as needed, which is both beautiful and practical.

2. Electrophoretic coating

Electrophoretic coating has a similar effect to spray coating, but it forms an organic coating on the surface of aluminum profiles, with rich and diverse colors, good decorative properties, and strong durability. Electrophoretic coating uses an electric field to uniformly deposit coating particles on the surface of aluminum, forming a uniform and dense coating. This processing method not only improves the corrosion resistance of aluminum, but also enhances its aesthetics.

3. Electrostatic powder spraying

Electrostatic powder coating is another important surface treatment method, which uniformly adsorbs powder coating onto the surface of aluminum profiles through electrostatic action, and then solidifies at high temperature to form a strong coating. This method has the advantages of diverse colors, good weather resistance, and strong impact resistance, and is widely used for external protection and decoration of industrial equipment.

4. Electroplating

Electroplating is the process of depositing a layer of other metals or alloys on the surface of aluminum profiles, commonly including nickel plating, silver plating, gold plating, zinc plating, copper plating, chromium plating, etc. Electroplating not only increases the corrosion resistance and wear resistance of aluminum materials, but also endows them with specific conductivity, aesthetics, and other properties as needed. There are various choices for electroplating layers, which can be customized according to the actual needs of the product.

2、 Mechanical processing method

1. Sandblasting

Sandblasting treatment is mainly used to reduce the surface roughness of aluminum profiles, improve adhesion, and provide a good foundation for subsequent surface treatments such as spraying and electrophoresis. During the sandblasting process, the high-speed sand particles impact the surface of the aluminum material, removing impurities such as oil and oxides, and increasing the surface roughness, which helps with the adhesion of the coating.

2. Polishing

Polishing treatment is the process of reducing the surface roughness of aluminum profiles through mechanical or chemical methods, making them smoother. Chemical polishing utilizes the selective self dissolution of aluminum in acidic or alkaline electrolyte solutions to level and polish the surface. Mechanical polishing uses tools such as grinding wheels and polishing paste to polish the surface of aluminum materials to achieve a smooth effect. The polished aluminum material not only has a beautiful appearance, but also improves the overall quality of the product.

3. Wire drawing

In modern industrial manufacturing, industrial aluminum profiles are widely used in various fields such as aerospace, automotive manufacturing, building decoration, and electronic equipment due to their excellent physical properties and processability. However, in order to improve the corrosion resistance, decorative and functional properties of aluminum profiles, surface treatment technology is particularly important.

3、 Comprehensive application and advantages

In practical applications, the surface treatment of industrial aluminum profiles is often not a single method, but a combination of multiple methods. For example, the combination of anodizing, spraying, electrophoretic coating and other technologies can not only improve the corrosion resistance of aluminum materials, but also enhance their aesthetics and functionality. In addition, with the development of technology, new surface treatment technologies continue to emerge, such as laser engraving, micro arc oxidation, etc., providing more possibilities for surface treatment of industrial aluminum profiles.

The diversity and flexibility of surface treatment technologies for industrial aluminum profiles enable them to meet the needs of different fields and products. By selecting and combining appropriate surface treatment methods, the performance and quality of aluminum materials can be significantly improved, providing strong support for the development of modern industrial manufacturing. In the future, with the continuous advancement and innovation of technology, the surface treatment technology of industrial aluminum profiles will become more mature and perfect, bringing more convenience and surprises to various industries. 试试AI翻译