How to control the quality of plywood production

Plywood, as a widely used material in the fields of furniture, construction, and decoration, directly affects the durability and safety of products due to its quality. Therefore, strict quality control is crucial in the production process of plywood. Here are some strategies on how to control the quality of plywood production.

Firstly, the selection of raw materials is fundamental. High quality logs are a prerequisite for producing high-quality plywood. When purchasing raw materials, strict selection of wood species, moisture content, texture, etc. should be carried out to ensure that each piece of wood meets production requirements. In addition, the quality of the adhesive cannot be ignored. Environmentally friendly and strong adhesive should be selected to ensure the strength and durability of plywood.

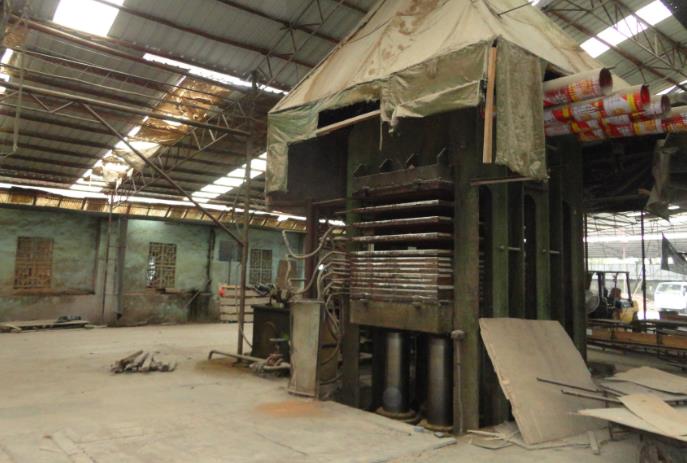

Secondly, the control of production processes is crucial. In the processing of plywood, precise control is required for cutting, splicing, gluing, pressing, and sanding. When cutting, ensure precise size, and when splicing, ensure natural texture and tight seams. The amount of glue applied should be moderate, ensuring both the bonding strength and avoiding excessive glue affecting product quality. The temperature, pressure, and time of the pressing process must be strictly controlled to ensure the structural stability of the plywood. Sanding is to obtain a flat and smooth surface, improve the aesthetics and usability of the product.

In addition, controlling the production environment is also very important. The temperature, humidity, and cleanliness of the production workshop can all have an impact on the quality of plywood. The temperature and humidity in the workshop should be maintained appropriately to reduce deformation and cracking of the wood. Meanwhile, the workshop should be kept clean to prevent dust and debris from contaminating the products.

Finally, strict quality inspection is the guarantee. Each batch of plywood should undergo sampling inspection, including checking its appearance quality, dimensional accuracy, bonding strength, and formaldehyde emission. For non-conforming products, they should be promptly reworked or scrapped to ensure that every product leaving the factory meets quality standards.

Controlling the quality of plywood production requires starting from multiple aspects such as raw material selection, production process control, production environment control, and quality inspection. Only in this way can we produce plywood products with stable quality and excellent performance, meet market demand, and win the trust and praise of consumers. At the same time, enterprises should continuously improve their quality control capabilities to adapt to the increasingly fierce market competition environment and achieve sustainable development.