What raw materials are needed to produce plywood

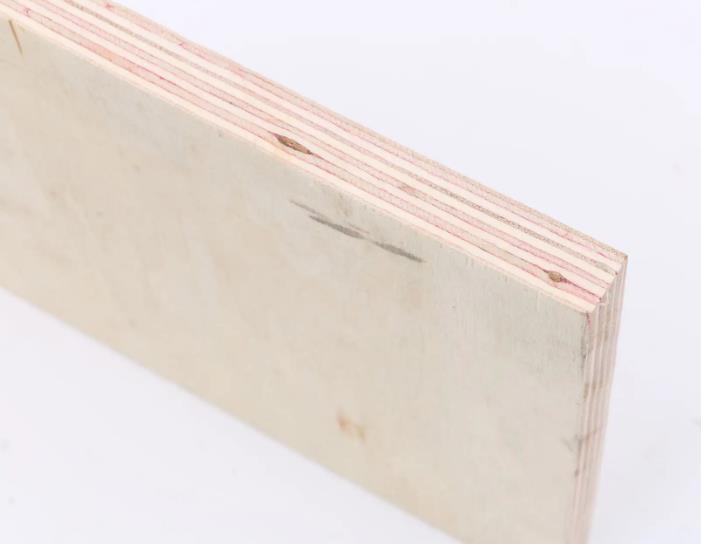

Plywood, as a widely used artificial board in furniture, construction, decoration and other fields, the selection and preparation of raw materials in its production process are crucial. The main raw materials required for producing plywood are analyzed, including their characteristics, uses, and selection criteria, with the aim of providing valuable references for relevant production enterprises and practitioners.

1、 The main raw materials for producing plywood

Wood raw materials

Wood is the main raw material for producing plywood, and its type and quality directly affect the performance and quality of plywood. Common wood materials include cedar, pine, birch, etc. These woods have the characteristics of uniform texture, clear texture, high strength, and are suitable for producing plywood of various specifications and purposes.

When selecting wood raw materials, the following points should be noted:

Raw material quality: High quality wood without defects such as insect infestation, decay, and cracks should be selected to ensure that the plywood produced has good physical and mechanical properties and appearance quality.

Moisture content: The moisture content of wood should be controlled within a certain range, usually requiring less than 10%, to ensure that the plywood produced has good dimensional stability and durability.

Specifications and dimensions: The wood raw materials need to be cut into wood chips of a certain length, width, and thickness according to production requirements for subsequent processing and assembly.

Glue raw materials

Adhesive is a key material in the production of plywood, which plays a role in tightly bonding multiple layers of wood together to form a sturdy and durable board. The commonly used adhesive materials include phenolic adhesive, urea formaldehyde adhesive, melamine adhesive, etc. These adhesive materials have good adhesive strength, water resistance, and heat resistance, and can meet the production needs of different plywood.

When selecting adhesive materials, the following points should be noted:

Adhesive strength: Adhesive materials with high adhesive strength should be selected to ensure that the plywood is not prone to delamination, cracking, and other phenomena during use.

Water resistance: The adhesive material should have good water resistance to prevent deformation, mold and other problems of the plywood in humid environments.

Environmental friendliness: With the increasing awareness of environmental protection, more and more enterprises are paying attention to the environmental performance of adhesive raw materials. Therefore, when selecting adhesive raw materials, priority should be given to environmentally friendly adhesives to reduce environmental pollution.

Other auxiliary materials

In addition to wood and glue raw materials, the production of plywood also requires some other auxiliary materials, such as preservatives, fire retardants, dyes, etc. These auxiliary materials play different roles in the production process of plywood, improving its performance, appearance, or meeting specific usage needs.

Preservatives: Preservatives are mainly used to prevent wood from being damaged by fungi, termites, and other organisms during storage and use. When choosing preservatives, attention should be paid to their anti-corrosion effect and environmental performance.

Fire retardant: Fire retardant can improve the fire resistance of plywood, allowing it to delay the spread of fire in the event of a fire. When selecting fire retardants, attention should be paid to their fire resistance and stability.

Dyeing agents: Dyeing agents can be used to change the color or texture of plywood to meet different decorative needs. When selecting dyeing agents, attention should be paid to their dyeing effect and environmental performance.

2、 Selection and preparation of raw materials

When producing plywood, it is necessary to comprehensively consider the selection and preparation of raw materials based on factors such as product usage requirements, production costs, and environmental requirements. Here are some suggestions:

Select appropriate wood and adhesive materials according to the product's usage requirements to ensure that the plywood produced has good physical and mechanical properties and appearance quality. Strictly control the moisture content of wood raw materials to ensure that the plywood produced has stable size and durability.

Priority should be given to selecting environmentally friendly adhesive raw materials and other auxiliary materials to reduce environmental pollution.

Strengthen the quality inspection and control of raw materials to ensure that the quality of raw materials meets production requirements.

The production of plywood requires the joint action of multiple raw materials, among which wood raw materials, adhesive raw materials, and other auxiliary materials are indispensable components. By selecting and controlling the quality and performance of these raw materials reasonably, high-quality and high-performance plywood products can be produced to meet the usage needs of different industries and fields. Meanwhile, with the increasing awareness of environmental protection and the promotion of environmental policies, future plywood production will pay more attention to the selection and application of environmentally friendly raw materials to achieve sustainable development.