China plywood machinery manufacturers produce complete machinery

In the global plywood industry, Chinese plywood machinery manufacturers are highly regarded for their complete production machinery. From raw material processing to final product output, each link is supported by sophisticated machinery, building an efficient and complete plywood production chain.

In the process of wood processing, Chinese machinery manufacturers provide advanced wood cutting machines. These cutting machines can accurately cut logs into suitable lengths according to different production needs. Its powerful power system and sharp saw blades can easily handle logs of various diameters and hardness, ensuring efficient and precise cutting process. At the same time, the log peeling machine is also an important equipment in this process. It can quickly and effectively remove the outer skin of logs, whether it is rough bark or stubborn impurities, which can be cleaned by the peeling machine, providing smooth and clean logs for subsequent processing.

Entering the stage of veneer processing, the rotary cutting machine plays a crucial role. The rotary cutting machines produced by Chinese manufacturers have a high level of automation and intelligence. It can evenly spin the logs into veneers of uniform thickness according to the set parameters. Whether it is adjusting the thickness of the veneer or controlling the cutting speed, precise operation can be achieved under advanced control systems. Moreover, these rotary cutting machines have high-quality cutting tools that can maintain sharpness for a long time, ensuring the quality and production efficiency of the veneer. Accompanying the rotary cutting machine is a veneer dryer, which can quickly dry wet veneers that have just been rotary cut. By precisely controlling parameters such as temperature, humidity, and ventilation, the moisture content of the veneer can meet production requirements in a short period of time, laying a solid foundation for subsequent bonding processes.

In the bonding and pressing process of plywood, Chinese manufacturers produce a wide variety of coating machines. There is a manual glue coating machine suitable for small-scale production, which is easy and convenient to operate; There are also automatic glue coating machines suitable for large-scale industrial production, which can achieve continuous and uniform glue coating operations. The hot press machine is the core equipment in this process. From traditional multi-layer hot press machines to advanced continuous hot press machines, Chinese manufacturers can produce them. Multi layer hot press can press multiple layers of plywood at once, improving production efficiency; A continuous hot press can achieve an uninterrupted production process, making the pressing of plywood more efficient and stable. These hot press machines have reached international advanced levels in pressure control, temperature uniformity, and other aspects, ensuring the bonding quality of plywood.

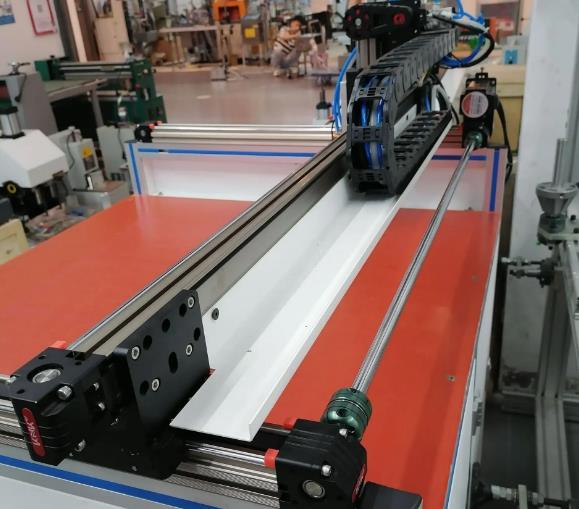

In the final processing and finishing stage, Chinese plywood machinery manufacturers also provide complete equipment. For example, a sawing machine can cut the edges of pressed plywood neatly, making the size of the plywood more precise. The sanding machine can finely polish the surface of plywood, remove surface defects and unevenness, make the surface of plywood smooth like a mirror, and improve the beauty and performance of the product.

In addition, Chinese plywood machinery manufacturers also produce various auxiliary equipment, such as material handling equipment, waste recycling equipment, etc. Material handling equipment can efficiently transport materials such as logs, veneers, plywood, etc. in the production workshop, improving the automation and efficiency of production. The waste recycling equipment can recycle and process the waste generated during the production process, achieve resource recycling, reduce production costs, and also meet environmental protection requirements.

The completeness of machinery produced by Chinese plywood machinery manufacturers not only meets the diversified needs of the domestic plywood industry, but also has won widespread praise in the international market. Whether it is a large plywood production enterprise or a small handicraft workshop, they can find machinery and equipment suitable for their production scale and process requirements in China. This not only promotes the rapid development of China's plywood industry, but also makes important contributions to the prosperity of the global plywood industry. In the future, Chinese plywood machinery manufacturers will continue to uphold the spirit of innovation, continuously enrich and improve their mechanical product lines, and provide the global plywood industry with higher quality and complete mechanical equipment.