The stable operation of plywood machinery is the cornerstone of ensuring production efficiency and product quality. Standardized daily maintenance can not only reduce sudden failures, but also significantly extend equipment lifespan.

[2025-11-25]

The production of wood plywood involves multiple processes, and equipment failures directly affect product quality and production efficiency.

[2025-11-01]

When selecting or evaluating a plywood hot press machine, one should not only look at the price, but also understand its several core technical parameters.

[2025-10-25]

Once the plywood hot press machine leaks oil, it will directly affect the production progress and product quality. To achieve rapid maintenance and restore production, please follow the following methods.

[2025-10-13]

Both cardless and cardless rotary cutting machines have their own advantages: the former excels in efficiency, flexibility, and low loss, while the latter wins with stability and accuracy.

[2025-09-23]

In the production process of plywood, the hot press machine is a key equipment, and its pressure calculation directly affects the quality and production efficiency of plywood. Many companies are often confused about how to accurately calculate the pressur

[2025-09-19]

The selection of specifications for plywood hot press machines should take into account factors such as production capacity, board thickness, and automation requirements.

[2025-09-18]

The cardless veneer rotary cutting machine, with its characteristics of no need for chuck fixation and more uniform wood stress, has a wider range of adaptability to wood than traditional equipment

[2025-09-04]

The veneer gluing machine is a key equipment for achieving uniform gluing of veneers in wood processing. Standardized operation not only ensures the quality of gluing, but also extends the service life of the equipment and avoids safety risks.

[2025-09-03]

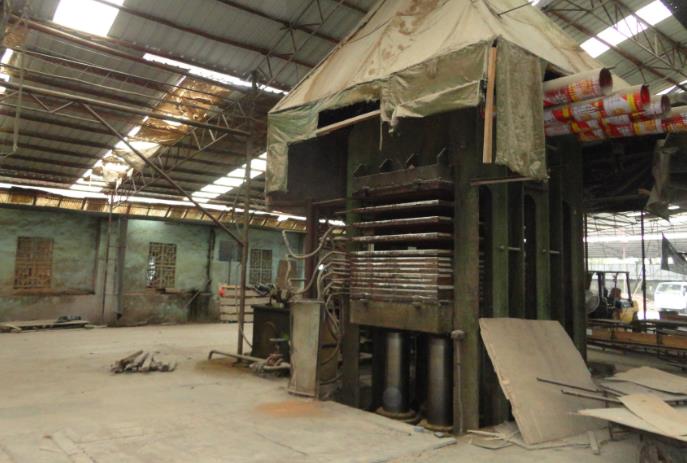

Plywood hot press machine is the core equipment in production, which uses heat and pressure to bond and solidify the slab. Its main structure is composed of the following precision systems

[2025-09-02]