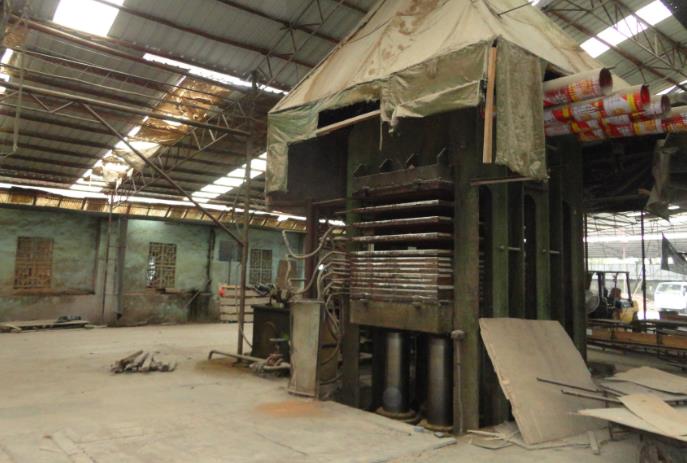

The function of ecological plywood hot press machine

In the production process of ecological boards and plywood, hot press machines play an indispensable role and are the core equipment for board forming.

The main function of a hot press is to tightly bond the materials of each layer of the board through high temperature and high pressure. When producing ecological boards, the decorative paper, substrate board, etc. are laid in order and then sent to the hot press machine. At high temperatures, the adhesive quickly activates, while high pressure ensures that different material layers are fully bonded, eliminating interlayer gaps and forming a stable whole, giving the board good flatness and strength.

For plywood, a hot press machine is also crucial. It bonds multiple layers of plywood with adhesive, and during the hot pressing process, the adhesive solidifies, enhancing the bonding force between the plywood and effectively preventing delamination, ensuring the mechanical properties and structural stability of the plywood.

In addition, the hot press can accurately control parameters such as thickness and density of the sheet metal. By adjusting the hot pressing temperature, pressure, and time, ecological boards and plywood that meet different usage and specification requirements can be produced. They are widely used in furniture manufacturing, building decoration, and other fields, and are an important guarantee for board quality and production efficiency.