How to choose advanced mechanical equipment suitable for plywood production

Plywood, as a widely used material in furniture, construction, decoration and other fields, cannot be produced without the support of advanced mechanical equipment. From the processing of logs to the manufacturing of finished plywood, every step requires precise and efficient equipment to ensure product quality and production efficiency. This article will explore how to choose advanced mechanical equipment suitable for plywood production from multiple aspects such as rotary cutting machines, dryers, glue making equipment, gluing machines, pre presses, hot presses, etc.

1、 Selection of rotary cutting machine

The rotary cutting machine is the first process in the production of plywood, responsible for cutting logs into single boards. When choosing a rotary cutting machine, the following aspects need to be considered:

Type selection: Rotary cutting machines are mainly divided into two categories: card cutting machines and non card cutting machines. The card rotary cutting machine has flexible operation and is suitable for logs of various diameters, but the equipment cost is relatively high; The card free rotary cutting machine is suitable for logs with relatively consistent diameters, and the equipment cost is relatively low. Enterprises should choose the appropriate type of rotary cutting machine based on their own raw material sources and production scale.

Accuracy and stability: The accuracy and stability of the rotary cutting machine directly affect the quality of the veneer. A high-precision rotary cutting machine can ensure uniform veneer thickness and reduce scrap rates. Therefore, when choosing a rotary cutting machine, attention should be paid to its accuracy and stability indicators.

Automation level: With the development of technology, rotary cutting machines with increasingly high automation levels have become the mainstream in the market. Automated rotary cutting machines can reduce manual operations, improve production efficiency, and reduce labor intensity. Enterprises should prioritize rotary cutting machines with high levels of automation.

2、 Selection of dryer

Veneer drying is a crucial step in plywood production, aimed at reducing the moisture content of the veneer for subsequent gluing and pressing. When choosing a dryer, the following factors should be considered:

Drying methods: Currently, the commonly used veneer drying methods include mesh drying, roller drying, veneer drying box, press veneer drying, and chimney evaporation drying. Enterprises should choose appropriate drying methods based on their own production needs and site conditions.

Drying efficiency: Drying efficiency directly affects the production cycle and cost. An efficient dryer can dry the veneer to the required moisture content in a short period of time, shorten the production cycle, and improve production efficiency.

Energy consumption control: During the drying process, energy consumption is high. Choosing a dryer with energy-saving and consumption reducing functions can reduce production costs and improve the competitiveness of the enterprise.

3、 Selection of glue making equipment and glue mixing machine

Gluing equipment and mixing machines are indispensable equipment in plywood production, as they directly affect the quality of plywood.

Glue making equipment: Glue making equipment should use products produced by professional manufacturers to ensure the quality and stability of the glue. Enterprises can choose rubber making equipment that is suitable for their production scale and raw material characteristics according to their own needs. Mixing machine: The mixing machine is used to mix glue to a viscosity suitable for application. When selecting a glue machine, attention should be paid to factors such as its blending effect, ease of operation, and maintenance cost.

4、 Selection of Gluing Machine

Gluing machine is a device that applies glue to veneer, and its performance directly affects the bonding quality and production efficiency of plywood.

Gluing method: There are two commonly used gluing machines: three roll and four roll. Enterprises should choose the appropriate gluing method based on production scale and veneer specifications.

Coating uniformity: Coating uniformity is an important indicator for measuring the performance of a coating machine. A high-quality gluing machine can ensure even gluing on the surface of the veneer and reduce the scrap rate.

Automation level: A highly automated gluing machine can reduce manual operations and improve production efficiency. Enterprises should give priority to gluing machines with high levels of automation.

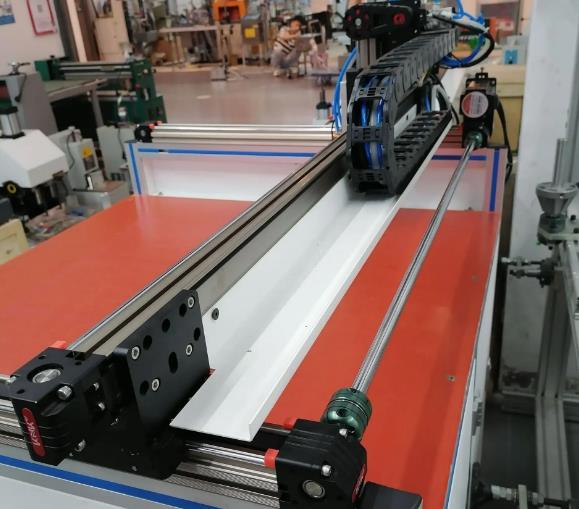

5、 Selection of pre press and hot press

Pre press and hot press are the core equipment in plywood production, which directly affect the quality and output of plywood.

Pre press: Pre press, also known as cold press, is used to pre press the glued veneer into a basic thickness. When selecting a pre press, attention should be paid to factors such as pressure stability, operational convenience, and maintenance costs.

Hot press machine: Hot press machine is a major process in the manufacturing of plywood, which directly affects the quality of plywood. When selecting a hot press machine, emphasis should be placed on its heating method, pressure control, temperature control, and automation level. High quality hot press machines can ensure that plywood is pressed at the optimal time, pressure, and temperature, thereby achieving the best quality of plywood.

6、 Selection of other auxiliary equipment

In addition to the core equipment mentioned above, plywood production also requires a series of auxiliary equipment, such as sanding machines, forklifts, sawing machines, etc. Although these devices do not directly participate in the pressing process of plywood, they also have a significant impact on production efficiency and product quality.

Sanding machine: Sanding machine is used to modify the surface of finished plywood and improve the surface quality of the product. When choosing a sanding machine, attention should be paid to factors such as its sanding effect, ease of operation, and maintenance cost.

When selecting advanced mechanical equipment suitable for plywood production, it is necessary to comprehensively consider the performance and automation level of core equipment such as rotary cutting machines, dryers, glue making and coating equipment, pre presses and hot presses, to ensure accurate raw material processing, efficient drying, uniform coating, and superior pressing quality. At the same time, the auxiliary role of sanding machines, forklifts, and other auxiliary equipment in production efficiency and product quality cannot be ignored. Comprehensive optimization of equipment configuration is the key to enhancing the competitiveness of plywood production.