What to do if one side of the lime kiln is overheated during calcination

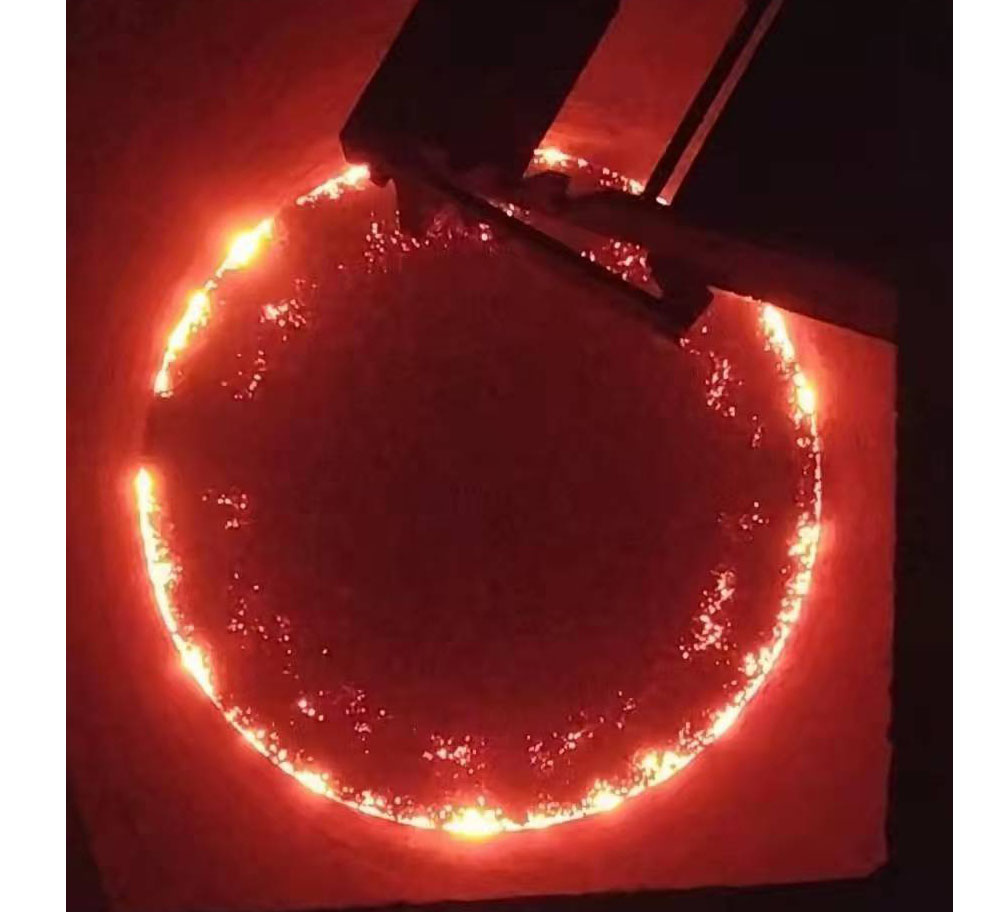

Lime kiln is an important equipment for lime production, and the stability of its combustion process directly affects the quality and output of lime. However, in the actual production process, there is often a phenomenon of one side of the lime kiln being overheated, that is, the flame inside the kiln is too strong on one side, while the other side is not burned enough. This phenomenon can lead to uneven calcination of lime, affecting its activity and other performance indicators. Therefore, effective measures must be taken to solve the problem of biased firing on one side of the lime kiln calcination.

Firstly, it is necessary to analyze the reasons for the biased fire. One side of the lime kiln may have a tendency to ignite due to various factors, such as uneven fuel distribution, poor air circulation, improper operation, and equipment aging or damage. Uneven fuel distribution can lead to excessive combustion in some areas and insufficient combustion in others. Poor air circulation may be due to inadequate sealing of the kiln body or blocked ventilation openings, resulting in uneven distribution of flames. Improper operation may manifest as the operator's failure to adjust the supply of fuel and air in a timely manner according to the actual situation inside the kiln. Equipment aging or damage, such as combustion chamber leakage, fan damage, etc., can also affect the uniformity of combustion.

To address these reasons, the following measures can be taken:

Adjust the fuel distribution to ensure even distribution within the kiln and avoid excessive or insufficient fuel on one side.

Check and improve the sealing of the kiln body to ensure that all parts of the kiln body are tightly connected and prevent air leakage from gaps. At the same time, regularly clean the ventilation openings to ensure that air can enter the kiln evenly and promote the full combustion of fuel.

Strengthen operational training to enhance the understanding and mastery of lime kiln combustion process by operators, enabling them to flexibly adjust the supply of fuel and air according to actual situations.

Regularly maintain and upkeep the equipment, promptly identify and address aging or damage issues, and ensure the normal operation of the equipment.

In addition, temperature, pressure and other sensors can be installed to monitor the combustion status in the lime kiln in real time, detect and deal with the phenomenon of misfires in a timely manner. During the adjustment process, attention should be paid to data collection and analysis in order to more accurately determine the cause and degree of fire deviation, and thus take more effective adjustment measures.

One side of the lime kiln calcination is prone to overheating, which is a problem that needs to be taken seriously. By adjusting fuel distribution, improving air circulation, strengthening operation training, and equipment maintenance measures, this problem can be effectively solved to ensure the stable operation and product quality of the lime kiln.