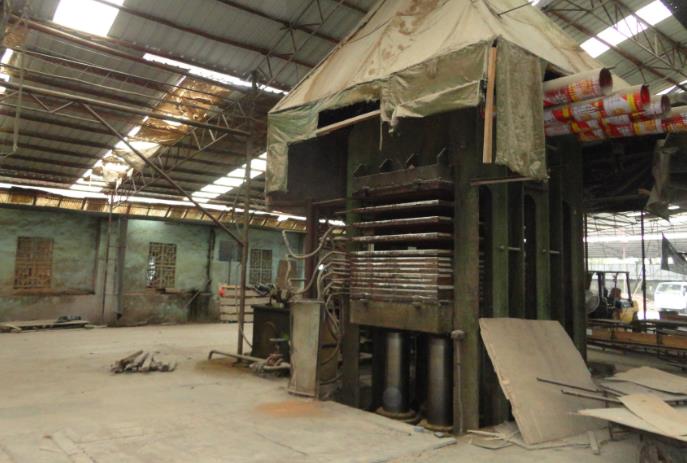

Common faults and efficient maintenance methods of plywood hot press machine

The plywood hot press machine is crucial in production, but some malfunctions often occur.

Oil cylinder leakage is one of the common problems, which may be caused by poor sealing or wear of the sealing ring, or corrosion of the piston surface. During maintenance, it is necessary to adjust or replace the sealing ring. If the surface of the piston is severely corroded, the piston should be replaced.

The hot press cannot start, which may be due to a malfunction of the main valve, failure of the low-pressure pump to deliver oil, failure of the accumulator oil delivery valve to open or low air pressure, or pipeline rupture or joint detachment. At this time, the return oil condition of the main valve, low-pressure pump, accumulator valve, air pressure, and pipeline should be checked and repaired accordingly.

The temperature of the hot press plate cannot rise, which may be due to water accumulation or blocked steam channels inside the hot press plate. To check the steam trap, drain the condensed water, and inspect the hot press plate that cannot be raised in temperature.

In addition, there may be indentations on the board surface, which could be due to uneven surface of the pad or the presence of adhesive blocks or debris. The pad should be replaced or cleaned in a timely manner.

To ensure the efficient operation of the hot press machine, daily maintenance is necessary, such as keeping the hot press surface flat and smooth, regularly disassembling the lining plate to remove dirt, and placing fiberboard pads when installing the lining plate. By timely maintenance and routine upkeep, it is possible to effectively reduce failures of the hot press machine, improve production efficiency, and enhance the quality of plywood.