Deep analysis of the working principle of plywood hot press machine

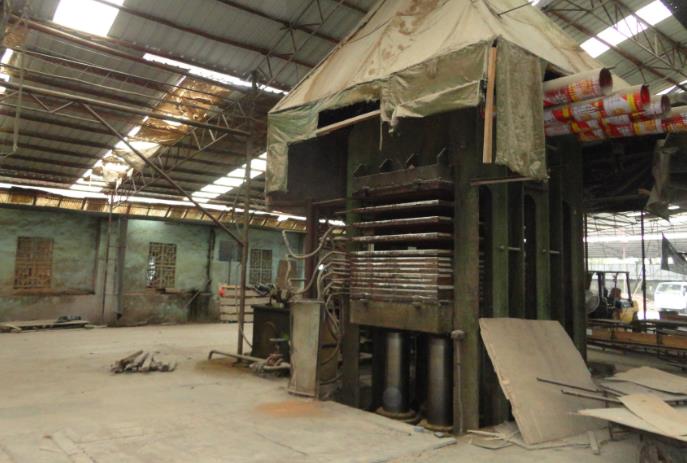

The plywood hot press machine is a key equipment in plywood production, and its working principle is based on the synergistic effect of heat and pressure.

When the hot press machine is working, first place the laminated slab to be processed between the hot press plates. The heating system is activated, such as using thermal oil for heating. The hot press plate is heated to the set temperature, and heat is transferred to the slab, causing the adhesive to soften and flow, enhancing the bonding ability.

At the same time, the hydraulic system drives the plunger type oil cylinder, which drives the hot press plate to quickly close and automatically pressurize. Apply pressure on the slab to eliminate bubbles and gaps between the layers, ensuring a tight bond between each layer. The pressure can be adjusted according to the process requirements, and the common pressure range is 1-20MPa.

During the hot pressing process, the temperature and pressure need to be precisely matched. Excessive temperature can cause wood to char, while insufficient temperature can result in incomplete curing of the adhesive; Insufficient pressure affects the bonding strength, while excessive pressure can easily damage the slab.

After the hot pressing is completed, the adhesive is cooled down through a cooling system to solidify and the slab is formed. Then the hot pressing plate is opened and the finished plywood is taken out. The entire process is automatically completed through time, pressure, and temperature control to ensure the quality and performance of the plywood.