What is the operation of lime kiln?

The operation of a lime kiln involves key steps such as ignition, observation, calcination, and control adjustment, each of which is crucial and directly related to the yield and quality of lime.

The ignition process is the prelude to the start of the lime kiln. Suitable fuels such as coke, coal gas, etc. need to be prepared in advance, and debris inside the kiln should be cleaned. Mix the fuel with the combustion aid in a specific order and proportion, and ignite carefully from the top of the kiln or designated location. At the initial stage of ignition, it is necessary to control the air flow to avoid extinguishing the flame, and closely observe the flame state to ensure stable combustion.

Watching fire work is like the "eyes" of a kiln. The operator needs to constantly pay attention to the color, shape, and combustion situation of the flame inside the kiln through the observation hole. A normal flame should be bright blue white. If the flame appears dark, flickering, or has black smoke, it may indicate insufficient fuel combustion or poor ventilation in the kiln, and should be adjusted in a timely manner.

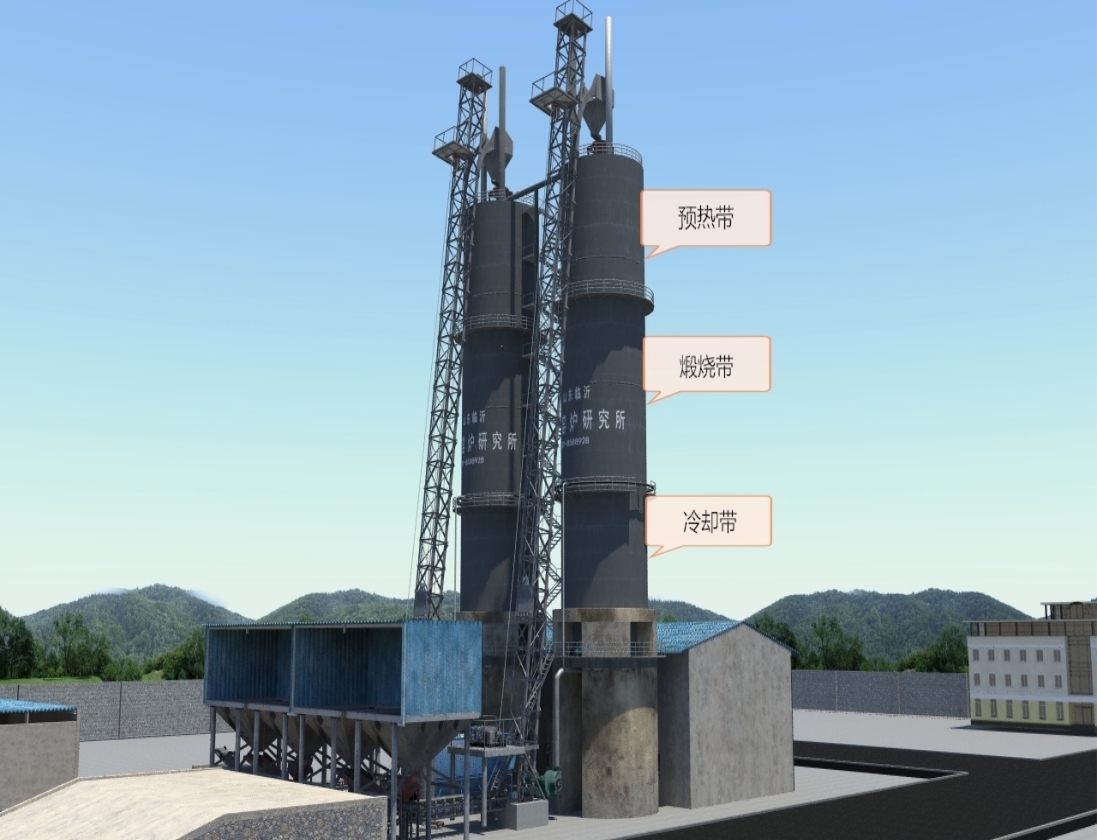

The calcination process is the core task of lime kilns. Reasonable control of calcination temperature and time should be based on factors such as limestone quality and kiln type characteristics. Excessive temperature can lead to overburning of lime and reduce its activity; If the temperature is too low, the lime burning rate will increase. By adjusting parameters such as fuel supply and ventilation, the temperature inside the kiln is stabilized within the optimal range.

Control and adjustment run through the entire production process. With the help of advanced monitoring equipment, real-time monitoring of parameters such as temperature, pressure, and gas composition inside the kiln can be achieved. Operating parameters can be adjusted in a timely manner based on data changes to ensure that the lime kiln is always in the best operating state, achieving efficient, high-quality, and stable production of lime.